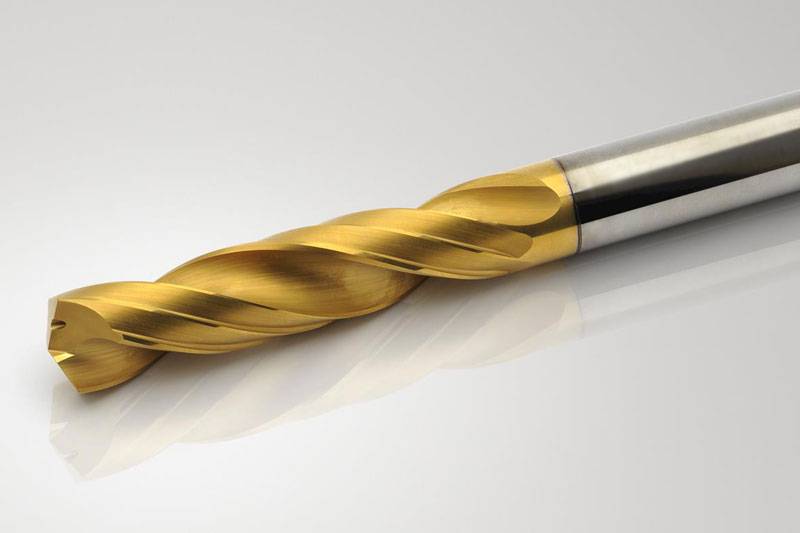

Drilling tools

The foremost thought in our engineers mind when visiting a customer is about the security and consistency of their operation and how they can get the most out of the machines they have on the shop floor.

In drilling applications, we consider materials, geometries, penetration rates, tool life and process security to reduce scrap as well as a myriad of other variables before recommending them the right product from our drilling tool range.

Security of the process is key

When looking at a new drilling process we assess insert wear, tip wear, edge wear and the life of the tool. We look for the happy medium between the cost of the tool and the value of the material being machined.

Giving peace of mind

Our engineers have enormous experience in selecting and trialing drilling tools. We’ll work alongside you to ensure that your chosen tool works with the right speeds and feeds to give you the outcome you want.

Why Choose Helix Tools?

Cutting metal is for specialists and Helix Tools has the technical knowledge and experience to support customers across any industry and any application.

Contact us-

Technical knowledge

-

Cutting specialist

-

Data driven

-

Impartial approach