Milling tools

Our engineers go through a mental checklist on a customer visit with the security and consistency of the operation being their premium concern.

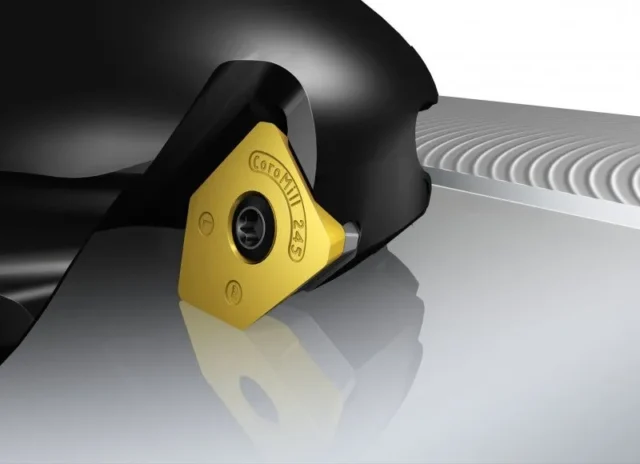

In milling applications, we consider the material and how to optimise metal removal rates while balancing tool life as well as vibration and a myriad of other variables before recommending the right product from our milling tool range.

Security of the process is key

When looking at a new milling application we consider all the options within the machine’s capabilities. Whether it be 90 degree, 45 degree or fast feed face milling, through to solid carbide multi flute end mills, barrel mills to the more conventional end mills, and ball nose cutters to name a few. At Helix we have the full choice of options to select from to maximise the metal removal rate.

Giving peace of mind

Our engineers have enormous experience in selecting and trialing milling tools. We’ll work alongside you to ensure that your chosen tool works with the right speeds and feeds to give you the outcome you want.

Why Choose Helix Tools?

Cutting metal is for specialists and Helix Tools has the technical knowledge and experience to support customers across any industry and any application.

Contact us-

Technical knowledge

-

Cutting specialist

-

Data driven

-

Impartial approach